Recent Projects

Air Cooled Electronics |

|

| Natural, forced and mixed convection, conduction and conjugate heat transfer from electronics packages, boards and systems for microelectronics and telecommunications applications. Specific topics that have been examined recently include: |

|

1. |

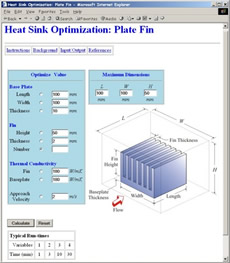

Culham, J.R., and Muzychka, Y.S., 2001, "Optimization of Plate Fin Heat Sinks Using Entropy Generation Minimization," IEEE Transactions CPT, Vol. 24, No. 2, pp. 159-165. Khan, W.A., Culham, J.R. and Yovanovich, M.M., 2005, "Optimization of Pin Fin Heat Sinks Using Entropy Generation Minimization," IEEE Transactions on Components and Packaging Technologies, Vol. 28, No. 2, pp. 247-254. |

2. |

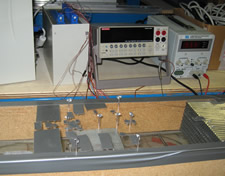

Leonard, W., Teertstra, P., Culham, J.R., and Zaghlol, A.,, 2002, "Characterization of Heat Sink Flow Bypass in Plate Fin Heat Sinks," Proceedings of IMECE 2002, International Mechanical Congress and Exposition, New Orleans, Louisiana, November 17-22. |

3. |

Fundamental research into analytical modeling techniques for natural and forced convection heat transfer for finite body shapes, such as spheroids, cuboids, and rectangular plates, enclosures, and cross flow heat exchangers and tube banks. Recent publications include: Khan, W.A., Culham, J.R. and Yovanovich, M.M.,, 2005, "Fluid Flow Around and Heat Transfer From an Infinite Circular Cylinder," ASME Journal of Heat Transfer, Vol. 127, No. 7, pp. 785 - 790. Teertstra, P., Yovanovich, M.M. and Culham, J.R.,, 2004, "Analytical Modeling of Natural Convection in Concentric Spherical Enclosures," Paper No. AIAA2004-0496, 42nd AIAA Aerospace Sciences Meeting and Exhibit, January 5-8, 2004, Reno, NV. |

Liquid Cooled Heat Sinks |

|

Recent publications include: Zugic, M.J., Culham, J.R., Teertstra, P., Horne, K., Knapp, E. and De Palma, J.-F., 2005, "Experimental and Analytical Investigation of Compact Liquid Cooled Heat Sinks," ASME International Mechanical Engineering Congress, Anaheim, CA, November 13-19. |

Heating and Ventilation Models for Automotive Seating Applications |

|

Recent publications include: |

Heat Sealing of Flexible Plastic Packaging |

|

|

Thermal Contact Resistance for Microelectronics Applications |

|

|

Effective Thermal Conductivity of Composite Thermal Interface Materials |

Recent publications include: |

Thermal Contact Resistance of Polymer-Polymer Joints |

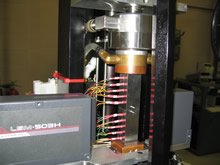

| This study looked at experimentally determining the TCR of a polymer/polymer joint under various interface contact pressures. Experimental data was then be compared to existing TCR models (both plastic and elastic). This entails having both the micro-hardness and the surface roughness of the polymer, both of which were looked at in detail. To experimentally determine the TCR of a polymer-polymer joint a minimal amount of heat must be used or the polymer samples will be permanently deformed. To ensure the polymer remains in a stiff, glassy state a polymer with a high glassy temperature must be used. Polycarbonate was selected for this reason and was the primary polymer used for this study. |

Evaluation and optimization of the thermal performance of heat sinks using entropy generation minimization (EGM) techniques. Heat sinks evaluated using these methods include plate fin and pin fin heat sinks, including both round and elliptical pins. Recent publications include:

Evaluation and optimization of the thermal performance of heat sinks using entropy generation minimization (EGM) techniques. Heat sinks evaluated using these methods include plate fin and pin fin heat sinks, including both round and elliptical pins. Recent publications include:  Measurement and modeling of flow bypass for plate fin heat sinks, including the effects of relative duct and heat sink sizes and geometries. The analytical expressions developed to describe flow bypass will be incorporated into an model that uses EGM to predict local air cooling limits for components located in larger systems. Recent publications include:

Measurement and modeling of flow bypass for plate fin heat sinks, including the effects of relative duct and heat sink sizes and geometries. The analytical expressions developed to describe flow bypass will be incorporated into an model that uses EGM to predict local air cooling limits for components located in larger systems. Recent publications include:  Design and testing of high capacity heat sinks developed specifically for use in power electronics, where high power dissipation rates preclude the use of conventional air cooled heat sinks. This research has involved:

Design and testing of high capacity heat sinks developed specifically for use in power electronics, where high power dissipation rates preclude the use of conventional air cooled heat sinks. This research has involved:

Development of simple and accurate models and algorithms for heat transfer and fluid flow in ventilated and heated car seats for the automotive industry. These models will provide the computational engine for CAD tools being developed in a joint project with NRC (London, ON) This research has involved:

Development of simple and accurate models and algorithms for heat transfer and fluid flow in ventilated and heated car seats for the automotive industry. These models will provide the computational engine for CAD tools being developed in a joint project with NRC (London, ON) This research has involved:

Analytical and experimental characterization of impulse sealing of heat-sealed polymer films. The process is widely used in the packaging of food products, medical supplies, etc. This research has involved:

Analytical and experimental characterization of impulse sealing of heat-sealed polymer films. The process is widely used in the packaging of food products, medical supplies, etc. This research has involved:

The current work in progress at the MHTL can be broken down into the following topics: This research has involved:

The current work in progress at the MHTL can be broken down into the following topics: This research has involved:

Recent publications include:

Recent publications include:

Particle-laden polymers are the latest Thermal Interface Materials (TIMs) being investigated for the minimization of thermal joint resistance in microelectronics applications. A fundamental problem which remains to be addressed is how to predict the effective thermal conductivity of these materials.

Particle-laden polymers are the latest Thermal Interface Materials (TIMs) being investigated for the minimization of thermal joint resistance in microelectronics applications. A fundamental problem which remains to be addressed is how to predict the effective thermal conductivity of these materials.  When heat flows through a contact formed at a polymer/polymer interface there is a temperature drop as a result of the thermal contact resistance (TCR) resulting from the imperfect contact.

When heat flows through a contact formed at a polymer/polymer interface there is a temperature drop as a result of the thermal contact resistance (TCR) resulting from the imperfect contact.